Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details

Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details

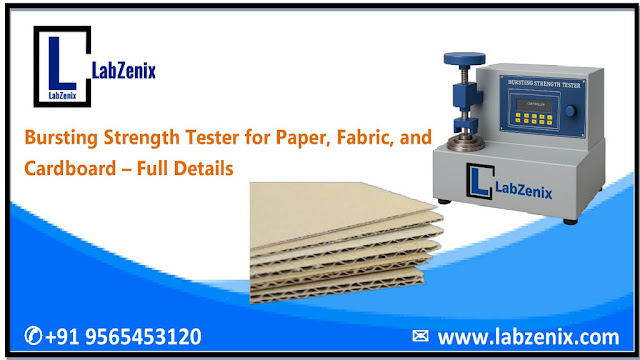

When it comes to quality control and product durability testing, one instrument stands out in the paper, textile, and packaging industries — the Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details. Whether you're a packaging manufacturer or textile supplier, maintaining material strength standards is essential. LabZenix, known for its innovation in precision instruments, provides cutting-edge bursting strength testers that meet industrial demands for high performance and reliability.

What is a Bursting Strength Tester?

A Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details is a lab-grade testing machine designed to evaluate the resistance of materials against rupture under pressure. It works by applying hydraulic or pneumatic pressure to the material until it bursts, then measuring the force required. The unit of measurement is typically in kg/cm² or psi.

This instrument is vital across various industries such as packaging, printing, textiles, and corrugated manufacturing. At LabZenix, every tester is developed with precision engineering, advanced sensors, and digital readouts to deliver consistent and repeatable results.

Why Use a Bursting Strength Tester?

Using a Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details offers numerous benefits:

-

Quality Assurance: Ensures that materials meet the required bursting strength standards.

-

Customer Satisfaction: Helps produce durable products that perform well during handling, transport, and usage.

-

Cost Savings: Avoids material wastage and reduces return rates due to poor-quality products.

-

Compliance: Fulfills testing standards such as ISO, ASTM, and TAPPI.

LabZenix testers help industries maintain international standards and deliver trust to their customers.

Key Applications of Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details

1. Paper Industry

Paper used in notebooks, documents, or packaging must withstand pressure. A Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details evaluates various paper grades, including kraft paper, duplex boards, and coated paper.

2. Fabric and Textile Industry

Textile materials like cotton, polyester, and blends require accurate testing to ensure tensile strength and durability. The Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details offers reliable testing for woven, non-woven, and knitted fabrics.

3. Corrugated and Cardboard Packaging

Carton boxes undergo multiple handling cycles. LabZenix testers measure the board’s strength to resist pressure and protect the contents, ensuring safe transit and storage.

Features of LabZenix Bursting Strength Tester

LabZenix offers both manual and digital bursting strength testers. Key features include:

-

Microprocessor-Based Display: Shows precise readings in real time.

-

Automatic Clamp Mechanism: Ensures uniform grip on the sample.

-

Calibration Facility: Allows easy and accurate calibration.

-

User-Friendly Operation: Simple control buttons and instructions.

-

Sturdy Construction: Heavy-duty frame for stability and long-term use.

Each Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details from LabZenix is calibrated as per ISO 2758 and IS 1060 standards.

How Does the Bursting Strength Tester Work?

The Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details works in a step-by-step process:

-

Sample Preparation: A flat specimen is placed between two clamping plates.

-

Hydraulic Pressure Application: The diaphragm pushes against the specimen.

-

Burst Detection: When the material ruptures, the pressure at the rupture point is recorded.

-

Reading Display: The final pressure value is displayed digitally or through an analog dial, depending on the model.

LabZenix ensures that every machine offers high accuracy, repeatability, and ease of use.

Types of Bursting Strength Testers Offered by LabZenix

Manual Bursting Strength Tester

Best suited for basic applications. Operators manually control the hydraulic flow.

Digital Bursting Strength Tester

Equipped with digital sensors and auto-stop functions, this version provides higher precision and eliminates human error.

Pneumatic Bursting Strength Tester

Uses air pressure instead of hydraulic pressure. Ideal for lightweight paper or thin fabrics.

Each Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details model by LabZenix is crafted to suit different industrial needs.

Standards and Certifications

LabZenix machines comply with several international standards, including:

-

ISO 2758 for paper

-

ISO 2960 for textiles

-

TAPPI T403 for corrugated boards

Compliance with these ensures that LabZenix delivers world-class performance and reliability.

Maintenance and Calibration

For accurate performance, periodic maintenance and calibration are essential. LabZenix offers complete support with:

-

Calibration Services

-

Spare Parts Supply

-

Annual Maintenance Contracts

-

User Manuals & Training

LabZenix ensures that the Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details performs optimally throughout its lifespan.

Common Industries Using Bursting Strength Testers

-

Printing and Packaging Units

-

Textile Manufacturing Plants

-

Corrugated Box Manufacturers

-

Label and Sticker Producers

-

Paper Bag and Envelope Producers

All these sectors benefit from LabZenix’s trusted Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details to maintain strength and durability.

Frequently Asked Questions (FAQs)

Q1: What is the importance of the Bursting Strength Tester for Paper, Fabric, and Cardboard – Full Details?

A1: It helps manufacturers ensure that materials used in packaging and textile applications are strong, durable, and capable of withstanding pressure, thus reducing product failure and increasing reliability.

Q2: How is bursting strength measured?

A2: It is measured by applying pressure via a rubber diaphragm until the material bursts. The pressure at the rupture point is recorded in kg/cm² or psi.

Q3: Which industries benefit most from using this tester?

A3: Packaging, textile, printing, and paper industries benefit the most as they rely on material durability for quality assurance and customer satisfaction.

Q4: Can the tester be used for multilayered materials?

A4: Yes, LabZenix testers are designed to test single-layer as well as multilayer materials such as laminated boards, composite textiles, and layered papers.

Q5: How often should the Bursting Strength Tester be calibrated?

A5: It is recommended to calibrate the tester every 6–12 months, depending on usage frequency and material type.

Q6: Does LabZenix offer warranty and support?

A6: Yes, all LabZenix testers come with a manufacturer warranty, technical support, and access to expert service for calibration and spare parts.

OES in metallurgical analysis plays a vital role in accurately determining the chemical composition of metals and alloys. Optical Emission Spectroscopy (OES) is widely used in metallurgy to detect both major and trace elements in ferrous and non-ferrous materials. This fast and reliable method is essential for quality control, material certification, and adherence to international standards. By using OES in metallurgical analysis, industries like steel manufacturing, foundries, and aerospace ensure consistent material properties, reduce defects, and maintain production efficiency. It’s the trusted solution for precision in metal testing.

ReplyDeleteElectrochemical Analyser measures electrical signals to study chemical properties of substances. Widely used in environmental monitoring, pharmaceuticals, and material science, it ensures accurate detection of ions, pH, and redox reactions.

ReplyDelete